Applications of Grinding Wheels

Grinding wheels are used in various industries and applications, including:

1. Metalworking and Manufacturing

In metalworking, grinding wheels are used for shaping and finishing metal parts. They are essential for sharpening tools, removing burrs, and creating precise dimensions in components.

2. Construction

Grinding wheels are used in the construction industry for cutting and grinding concrete, masonry, and stone. Diamond grinding wheels are particularly useful for cutting through tough materials like reinforced concrete.

3. Automotive and Aerospace

In the automotive and aerospace industries, grinding wheels are used to produce high-precision parts and components. They are used for grinding engine parts, turbine blades, and other critical components that require tight tolerances.

4. Tool and Die Making

Grinding wheels are essential in tool and die making for creating molds, dies, and precision tools. They are used to grind and finish the surfaces of these tools to ensure they meet the required specifications.

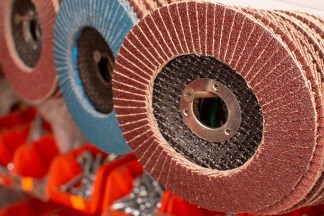

Materials Used in Grinding Wheels

1. Abrasive Grains

The abrasive grains are the cutting elements of the grinding wheel. Common materials include:

-Aluminum Oxide: Suitable for grinding carbon steel, alloy steel, high-speed steel, and wrought iron.

-Silicon Carbide: Ideal for grinding cast iron, non-ferrous metals, and non-metallic materials.

-Diamond: Used for grinding extremely hard materials like ceramics, glass, and carbide.

2. Bonding Materials

Bonding materials hold the abrasive grains together and provide the wheel with its shape and structure.

3. Wheel Structure

The structure of the grinding wheel refers to the spacing between the abrasive grains.

Catalogue

Catalogue