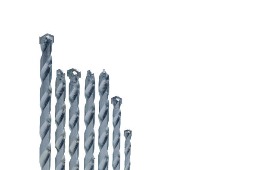

Parts of Twist Drill Bits

1.Point (Tip): The leading end of the drill bit that makes contact with the material to be drilled. The point is typically ground to a specific angle depending on the material being drilled.

2.Flutes: The spiral grooves that run along the length of the drill bit. Flutes serve multiple purposes, including facilitating chip removal, cooling the bit during operation, and providing a path for the cutting edges.

3.Cutting Edges: The sharp edges along the sides of the point where the drilling action occurs. The number of cutting edges can vary, and each edge is responsible for cutting into the material as the bit rotates.

4.Shank: The shank is the opposite end of the drill bit from the point. It is the part that is inserted into the chuck of a drill or other drilling device. The shank can be straight or have a tapered design, depending on the size of the drill bit.

5.Helix Angle: The angle formed by the flutes' helical shape. The helix angle affects the chip removal process and is an essential factor in the drill bit's design.

6.Web: The central portion that connects the flutes. The thickness of the web influences the strength and rigidity of the drill bit.

7.Chisel Edge: The edge formed by the intersection of the point and the flute. It helps to guide the drill bit into the material and contributes to the cutting action.

Twist drill bits come in a wide range of sizes and materials, allowing them to be used for various applications. They are commonly used in hand drills, drill presses, and other drilling machinery. The selection of a specific twist drill bit depends on factors such as the material being drilled, the desired hole size, and the type of drilling equipment available.

Catalogue

Catalogue